Revisited: Billet Isn’t Everything — The Rise of Aftermarket Cast Engines.

- Av

- Episod

- 296

- Publicerad

- 19 dec. 2024

- Förlag

- 0 Recensioner

- 0

- Episod

- 296 of 323

- Längd

- 1T 24min

- Språk

- Engelska

- Format

- Kategori

- Personlig Utveckling

*** We’ll be taking a break over the Christmas/New Year period and will be back in action mid-January.

That means that although there won’t be any new episodes for a few weeks, we’ll be taking another look at some of our favourite conversations from 2024. ***

Over the last few years, we’ve seen a massive increase in the availability of ultra-high-performance billet parts — especially blocks and heads. This week’s guest, Chris Smith of Crest CNC, was one of the pioneers of this practice in the import category, but now he’s branching out from the 5-axis CNC and heading to the foundry to produce cast engine parts — we find out why.

Use “CREST50” to get 50% OFF our HPA 3D Modelling & CAD for Motorsport course: https://hpcdmy.co/CADb

Chris Smith came up in the trade as an engine reconditioner, before buying his first CNC mill and starting on a career path that would eventually see his business become the go-to supplier of billet blocks and heads for some of the world’s fastest racers, as well as the odd OEM manufacturer.

This week’s conversation first jumps into the ins and outs of metallurgy and tribology (which, by the way, is the study of interacting surfaces in motion). We learn the difference between various materials commonly used in high-end performance applications — like 6061 and 7075 aluminium, for example — as well as the pros and cons of different 3D scanning tools, coordinate measuring machines, and CAD software.

The conversation then steers itself towards the weaknesses of both Nissan’s VR38 and Subaru’s EJ motors, delving into how failures occur and how Chris addressed them with his billet block and head offerings. While on the subject, Chris also goes into detail on the advantages and disadvantages of wet and dry cylinder sleeves, as well as the reliability and maintenance requirements of billet engines.

This naturally brings us to the elephant in the room — why a billet engine specialist is now offering aftermarket cast engine products. Chris lays down the reasons why it’s a good idea, and takes pains to explain how aftermarket cast is very different from the cast blocks and heads that come off an OEM manufacturer’s production line.

Are aftermarket cast engine parts the way of the future? Listen to this episode with Chris Smith of Crest CNC and come to your own conclusion.

As discussed, you can listen to Tony Palo’s episode here: https://hpcdmy.co/tonypalo

Follow Crest CNC here: IG: @crest_cnc_pty.ltd FB: CREST CNC PTY. LTD. TIKTOK: @Crest_CNC WWW: crestcnc.com

Don’t forget, you can use “CREST50” to get 50% OFF our HPA 3D Modelling & CAD for Motorsport course: https://hpcdmy.co/CADb

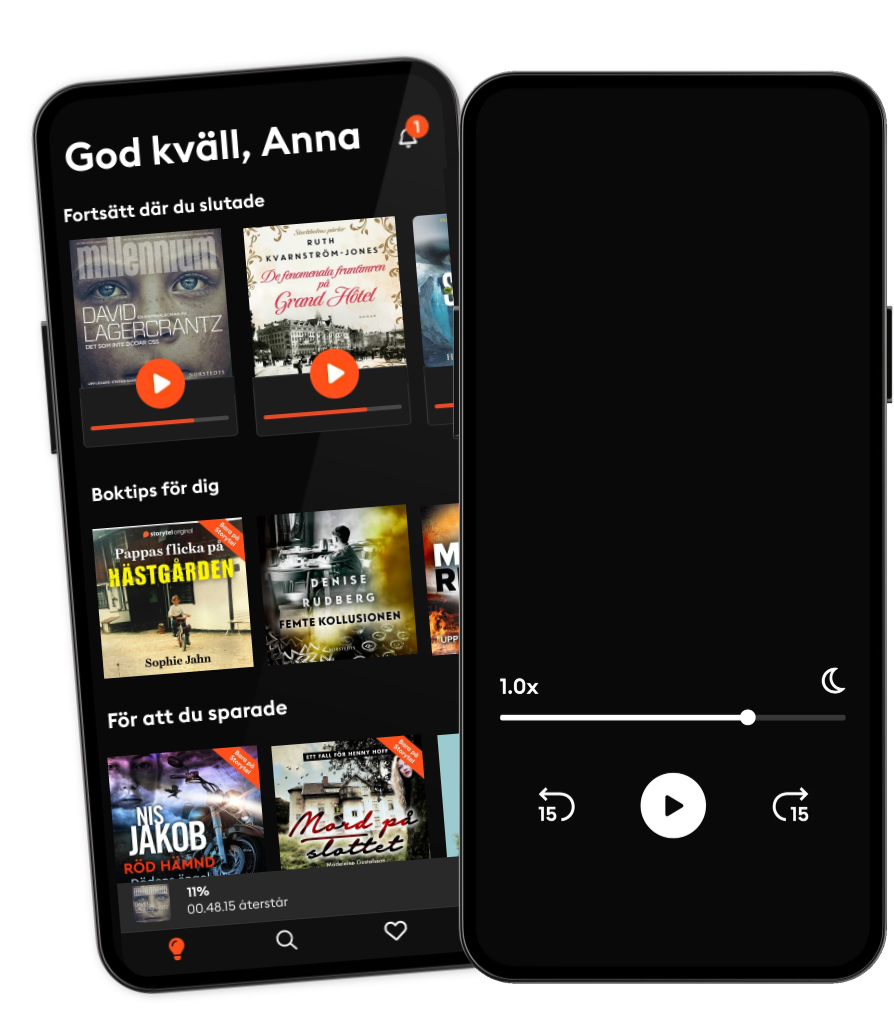

Lyssna när som helst, var som helst

Kliv in i en oändlig värld av stories

- 1 miljon stories

- Hundratals nya stories varje vecka

- Få tillgång till exklusivt innehåll

- Avsluta när du vill

Andra podcasts som du kanske gillar...

- Stærke portrætterALT for damerne

- Sotto pressione - Come uscire dalla trappola del burnoutAlessio Carciofi

- IgnifugheFederica Fabrizio

- Rise With ZubinRise With Zubin

- SEXPANELETEmma Libner

- VoksenkærlighedAmanda Lagoni

- Informe de los bosquesPodium Podcast

- Something Was WrongBroken Cycle Media | Wondery

- Peter pratar bostadsköpPeter Dittmer

- Minimal-ish: Minimalism, Intentional Living, MotherhoodCloud10

- Stærke portrætterALT for damerne

- Sotto pressione - Come uscire dalla trappola del burnoutAlessio Carciofi

- IgnifugheFederica Fabrizio

- Rise With ZubinRise With Zubin

- SEXPANELETEmma Libner

- VoksenkærlighedAmanda Lagoni

- Informe de los bosquesPodium Podcast

- Something Was WrongBroken Cycle Media | Wondery

- Peter pratar bostadsköpPeter Dittmer

- Minimal-ish: Minimalism, Intentional Living, MotherhoodCloud10

Svenska

Sverige