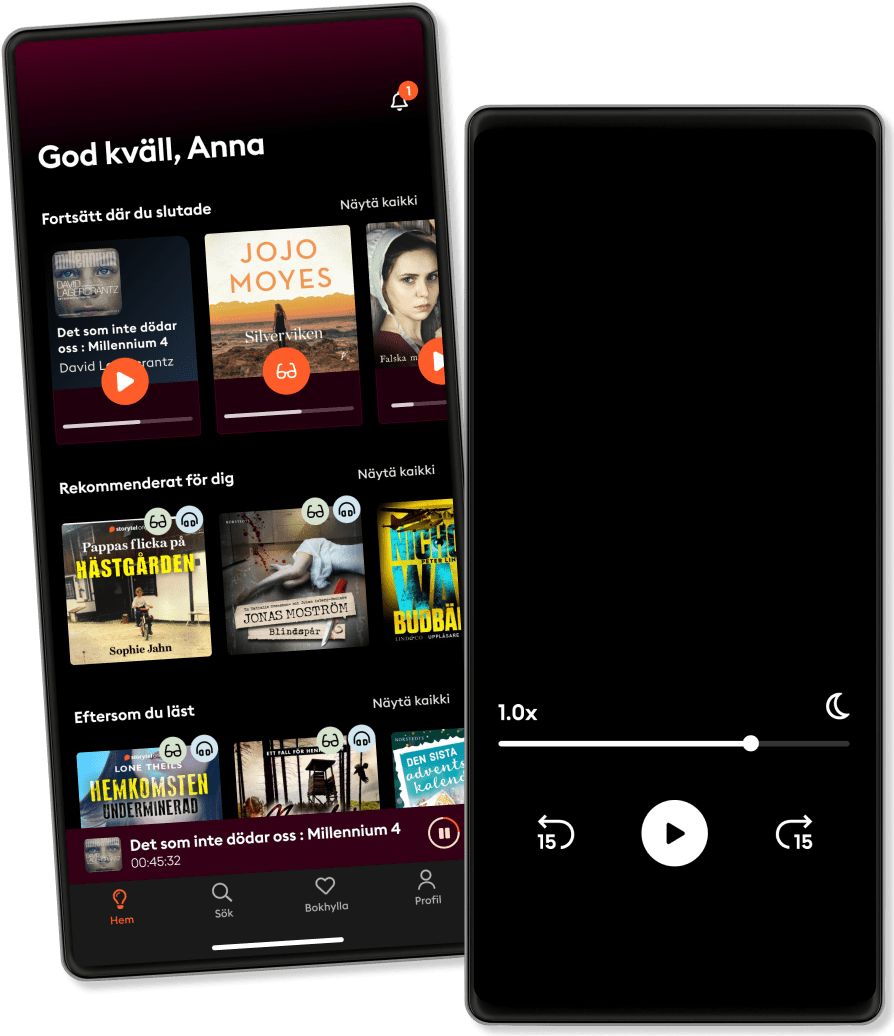

Dengarkan dan baca

Masuki dunia cerita tanpa batas

- Baca dan dengarkan sebanyak yang Anda mau

- Lebih dari 1 juta judul

- Judul eksklusif + Storytel Original

- Uji coba gratis 14 hari, lalu €9,99/bulan

- Mudah untuk membatalkan kapan saja

Manufacturing of Concrete Products and Precast Elements: Processes and Equipment

- Bahasa

- Inggris

- Format

- Kategori

Non Fiksi

The flexible use of prefabricated concrete products requires a continuously increasing diversity with regard to fresh concrete mix designs and properties, moulding processes, surface finishes and product characteristics.

This trend imposes ever-higher requirements on manufacturers of the associated production equipment and on precast plants. The main goal is to implement a flexible production system in all processing stages. The relevant correlations and interactions need to be thoroughly considered and evaluated in order to ensure that concrete products and precast elements are manufactured to the required quality standard.

To date, no comprehensive description of these correlations has been published in the relevant literature. This richly illustrated book closes the gap by describing the basic principles of the production processes, the fundamentals of materials, the composition of the concrete mix, and the equipment used for concrete production. Clearly arranged chapters detail the production processes and equipment used to manufacture small concrete products, concrete pipes and manholes, and precast elements.

The authors have used their many years of experience in the field of precast technology and their close ties to the industry. Their aim was to integrate modern testing and calculation methods from neighbouring disciplines into precast technology. This includes, for instance, modelling and simulation of the workability behaviour of mixes, implementation of the latest advancements in machine dynamics to the design and engineering of production equipment, and the use of state-of-the-art measuring and automation technology for quality control purposes.

© 2013 Verlag Bau+Technik (buku elektronik ): 9783764005382

Tanggal rilis

buku elektronik : 20 Maret 2013

Tag

Yang lain juga menikmati...

- Risk Management: Concepts and Guidance, Fifth Edition Carl L. Pritchard PMP PMI-RMP EVP

- The Intelligent Investor Benjamin Graham

- Six Sigma For Dummies Bruce Williams

- Being Human: Life Lessons from the Frontiers of Science Robert Sapolsky

- Building the Future: Big Teaming for Audacious Innovation Amy Edmondson

- Managing productive maintenance: best practices to eliminate equipment failures and maximize productivity Harilaus Xenos

- The Lean Product Playbook: How to Innovate with Minimum Viable Products and Rapid Customer Feedback Dan Olsen

- The E-Myth Accountant: Why Most Accounting Practices Don’t Work and What to Do about It Michael E. Gerber

- Dollars and Sense: How We Misthink Money and How to Spend Smarter Dan Ariely

- A Degree in a Book: Electrical And Mechanical Engineering: Everything You Need to Know to Master the Subject - in One Book! David Baker

- 8 Intisari Kecerdasan Finansial Indra

4.9

- Sang Alkemis Paulo Coelho

4.8

- Bumi Tere Liye

4.6

- Rumah Lebah Ruwi Meita

4.4

- Pribadi Hebat Buya Hamka

4.9

- Hujan Tere Liye

4.6

- Selamat Tinggal Tere Liye

4.6

- Di Bawah Lindungan Ka'bah Buya Hamka

4.1

- Ronggeng Dukuh Paruk Ahmad Tohari

4.7

- Resign! Almira Bastari

4.2

- Dunia Sophie Jostein Gaarder

4.8

- Days at the Morisaki Bookshop: A Novel Satoshi Yagisawa

3.8

- Terusir Buya Hamka

4.5

- Dua Dini Hari Chandra Bientang

3.8

- The Naked Traveler Trinity

4.1

Selalu dengan Storytel

Lebih dari 900.000 judul

Mode Anak (lingkungan aman untuk anak)

Unduh buku untuk akses offline

Batalkan kapan saja

Premium

Bagi yang ingin mendengarkan dan membaca tanpa batas.

1 akun

Akses Tanpa Batas

Akses bulanan tanpa batas

Batalkan kapan saja

Judul dalam bahasa Inggris dan Indonesia

Premium 6 bulan

Bagi yang ingin mendengarkan dan membaca tanpa batas

1 akun

Akses Tanpa Batas

Akses bulanan tanpa batas

Batalkan kapan saja

Judul dalam bahasa Inggris dan Indonesia

Local

Bagi yang hanya ingin mendengarkan dan membaca dalam bahasa lokal.

1 akun

Akses Tanpa Batas

Akses tidak terbatas

Batalkan kapan saja

Judul dalam bahasa Indonesia

Local 6 bulan

Bagi yang hanya ingin mendengarkan dan membaca dalam bahasa lokal.

1 akun

Akses Tanpa Batas

Akses tidak terbatas

Batalkan kapan saja

Judul dalam bahasa Indonesia

Bahasa Indonesia

Indonesia